Inefficient workflows and production processes leading to increased costs.

Vulnerability to supplier delays and material shortages impacting production schedules.

Maintaining high-quality output while managing costs and productivity.

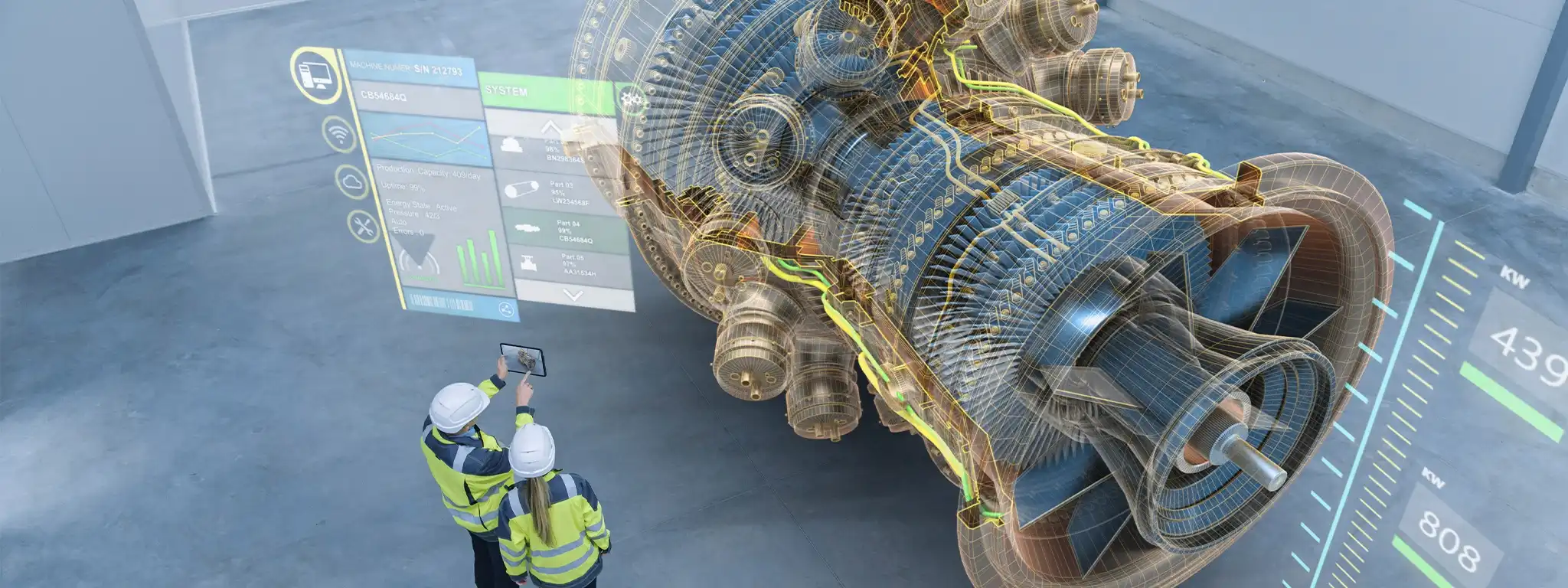

Utilizing simulation tools hosted on platforms like Google Cloud to create virtual replicas of physical assets and processes.

Cloud-based APIs to connect manufacturing data from various systems (sensors, ERP).

Google BigQuery for processing historical production data and running machine learning models for predictive analytics.

Looker dashboards for monitoring production efficiency metrics.

Enhanced understanding of process efficiencies and areas for improvement.

Identification and remediation of bottlenecks in workflows.

Through optimized resource allocation and reduced unplanned downtime.

Quicker response to changing market demands and product launches.

Enhanced precision in manufacturing processes leading to fewer defects.